2020 Blog

Basic Best Practices on How to Make your Vinyl, CD and Special Packaging Releases as Sustainable as Possible

At Key Production Group we aim to Package Responsibly and we are actively moving toward making your releases as sustainable as possible. A great deal of research on this subject has already been published but, here we hope to provide some practical advice on how to reduce the impact of physical music formats on the global climate.

Our founder and CEO Karen Emanuel has always been active on this front, supporting associations such as Julie’s Bicycle from the outset, and, more recently, contributing to meetings focussing on sustainability with ERA, the BPI, BBC and AIM to share her 30 years of experience and knowledge of the subject. Karen has also been participating in panels with Music Declares Emergency and is directly addressing and encouraging our suppliers regarding measures they are taking to address the urgent necessity for a greener music industry.

Our range of products is as wide as our customers’ imaginations, so check with us what measures are available to keep your specific product as environmentally friendly as possible.

Made to Last: Spin it Don’t Bin it

A beautiful product makes an emotionally durable possession. If the object of physical music formats is to establish a bond between artist and fan, then these formats are designed and produced to be cherished by their owners. Our strongest memories are often those associated with music. Collections are valued, constantly revisited and even passed on to subsequent generations: making them the antithesis of a single-use or disposable product. Options are available to ensure best practice in manufacturing these items to improve their sustainability and minimise their carbon footprint.

Significant progress toward sustainability has been made within the industry since Key started back in 1990. We have constantly pursued that goal and continue to do so. Below are some suggestions of best practices you can consider when manufacturing your physical release.

Vinyl Eco-Mix

This clever idea uses up leftover coloured pellets from previous vinyl runs, mixes them together and produces a run of randomised ‘lucky-dip’ colour vinyl. This cuts down on waste and can also result in some impressive colours. Every single record pressed with the Eco-Mix has its own individual colour and effect. This can be a great incentive for fans wishing to own something unique while at the same time helping reduce the product’s environmental impact. And it’s cheaper than regular coloured vinyl!

Many plants can also offer the option to use a proportion of re-ground black vinyl which is taken from the offcuts left from regular black vinyl orders and mixed with new “virgin” vinyl, to reduce waste.

Less Is More: 140g Vinyl beats 180g in Sustainability

Every little helps, and although heavy vinyl can lend your record more substance and perceived value, 140gram vinyl has a proportionally lower carbon footprint than 180gram with regard to manufacturing and shipping.

Think Beyond Shrinkwrap

While the majority of our customers do still choose to shrink-wrap new product, shrink-wrap generates an insignificant proportion of the carbon emissions created in the manufacture of each product. When Key started in 1990, we rarely shrink-wrapped manufactured product but the way that consumers buy music has changed, and most product is now shrink-wrapped to reduce unavoidable damage in transit and retail.

It can be argued that removing shrink-wrap results in more waste due to the greater return of damaged stock. Conventional PE/PP film is recyclable (although, as with other plastics, only certain councils currently recycle). There are some newer films on the market (BYO and BOPLA) that are oxo-biodegradable but there is still controversy over whether the components into which they break down are themselves harmful to the environment.

All plants are working with suppliers to produce fully biodegradable shrink-wrap. We can offer PVC outer sleeves as an alternative to disposable, one-use shrink wrap, or printed paper “belly bands” which can seal the product without using any plastic packaging.

Run from the Jewel

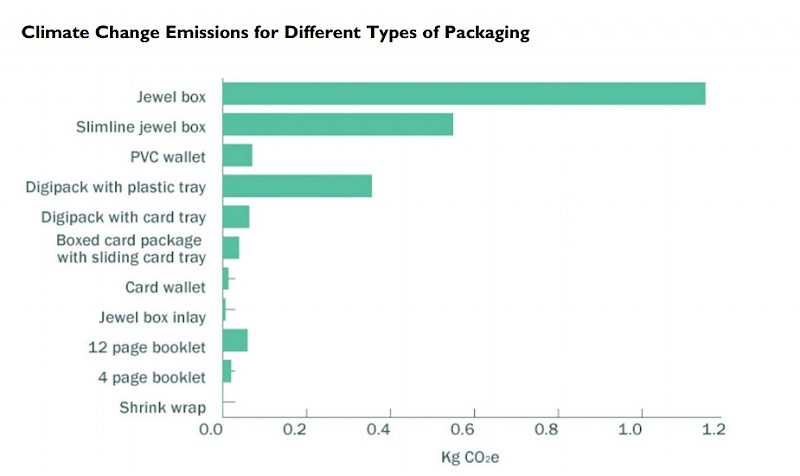

In 2007, Julie’s Bicycle, a London based charity that supports the creative community to act on climate change and environmental sustainability, commissioned a study titled “Impacts and Opportunities Reducing the Carbon Emissions of CD Packaging” from the Environmental Change Institute. This investigation into the carbon footprint of the UK Music Industry revealed that one of the most intensive sources of carbon emissions is plastic packaging for CDs. The report provided a detailed analysis of packaging options and stated that the recording industry could reduce its packaging emissions by up to 95% by switching from plastic jewel cases to card packaging.

Graph from Julie’s Bicycle Report 2009 (Please note: the manufacture of a compact disc generates approximately 9% of the emissions associated with the entire CD product as compared to packaging which produces in the region of 34% and a further 6% with a 12-page booklet.)

Since then, CD products have been moving away from plastic packaging. No more recent data has been collated, but we do suggest continued avoidance of CD plastic cases in favour of card options. Well-designed card packaging can look terrific and is a much greener option.

This said, Amaray has recently produced a box that can be made from post-consumer waste and is lighter than standard plastic boxes. It is currently being trialled.

All about Sustainable FSC-certified Paper, Card Stocks & Vegetable Inks

Sustainable FSC-certified paper and card stocks, low-carbon packaging options, the highest quality vegetable-based inks, premium water-based varnishes, and compliance with environmental industrial standards including ISO 14001 are the minimum we expect, and accept from our suppliers.

ISO14001 is the internationally agreed standard that sets out the requirements for an environmental management system. Many of our suppliers are also Sony certified green partners and are FSC certified and ISO50001 (certified energy management system) and ISO9001 (quality management) accredited.

One thing to be mindful of, if you wish for your release to be as eco-friendly as possible, is to consider avoiding certain special finishes on your card product. Extra processes like UV varnishes and laminate or foil finishes make waste left over from manufacture very difficult or impossible to recycle, as they turn a recyclable card into one with mixed materials – the enemy of all recycling plants.

Special Packaging: From Foam to Paper

For box sets consider a card fitment instead of foam. It’s recyclable and keeps all your items in place.

Clever Management of Deliveries

Transport of your finished stock is also a consideration. Intelligent forecasting and careful planning help Key minimise any unnecessary impact in the transport of goods by ensuring vehicles are carrying optimum capacity.

For example, if you have European stock being made in Europe, we can arrange direct delivery within Europe for you.

Please do ask us to advise you on how to better manage your deliveries. We are happy to help you help the planet.

Carbon Balancing

Key Production chooses its suppliers not only on their ability to deliver the high quality we demand, but also on their ability to demonstrate ecological sustainability in their business practices, ensuring their environmental impact is mitigated.

All of our suppliers are continually updating processes to make their facilities better ecologically, re-using vinyl waste in vinyl production, recycling all card waste, using waste energy to heat offices and introducing carbon offsetting.

Recycling

We know that mistakes can be made and sometimes you can end up with overstocks which need to be disposed of. Distributors will usually have a responsible recycling scheme of their own so please check there first, but we are also working towards providing a central recycling hub where we can guarantee that every element of a product is being recycled responsibility, for those occasions when a distributor can’t help.