2020 Blog

Apollo/Transco Lacquers Factory Fire Won't Cause any Disruption to Key Production Services

With the sad news of the fire at Transco in the USA on Friday, we want to take the opportunity to reassure customers that there should be no disruption to Key Production’s vinyl manufacturing services.

Prior to the fire, blank lacquers were supplied by either Transco in the USA or MDC in Japan. Many of the reports about the Transco fire reported that MDC would not be able to take on any new clients.

With this in mind, all of our main suppliers of lacquer cutting services have a pre-existing supply arrangement with MDC. MDC already supply a much higher percentage of the European market than Transco, and they have no plans to reduce the supply to European factories and cutting houses.

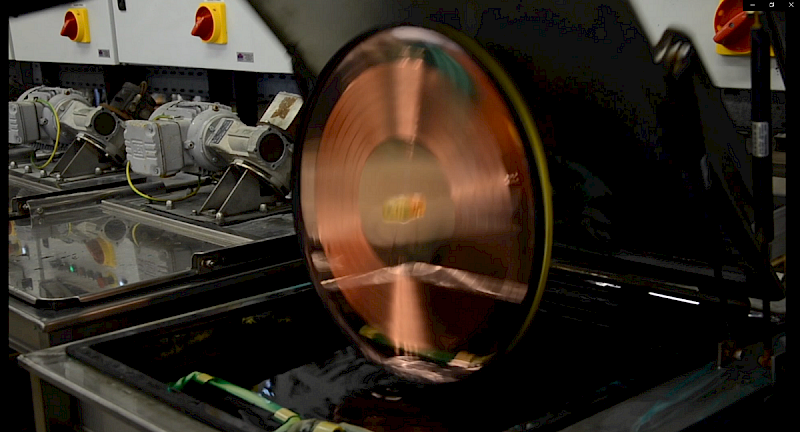

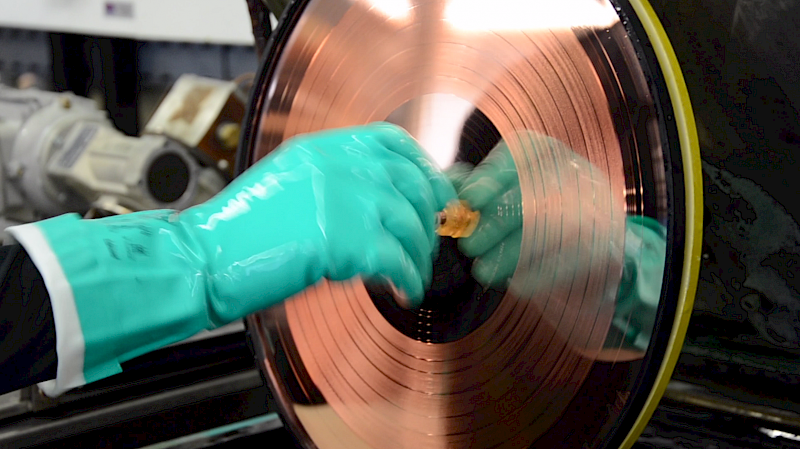

In addition to this, the majority of our factories have DMM cutting facility, which cuts on to a copper-plated disc, not onto a lacquer. If necessary DMM capacity at these factories can be increased to meet any rise in demand.

While it is possible that the loss of Transco will have an effect on the vinyl industry as a whole, Key Production does not expect any disruption to our manufacturing services and are confident that all our supply partners have sufficient contingency plans to deal with the loss of one lacquer supplier.

What is a lacquer? Where does it stand in the vinyl pressing process? What's the difference with DMM?

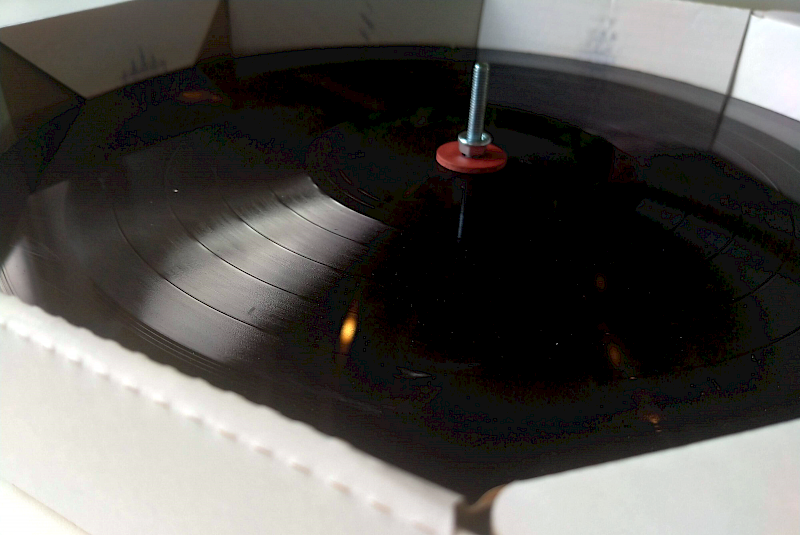

Lacquers stand at the very beginning of the vinyl production process. Once your vinyl record masters and order are received, we cut the audio to either lacquer or direct to copper plates (DMM) depending on various factors, such as overall sound volume, program length and musical style.

Lacquers are created on a special lathe which looks like a large record player and works rather like a record player's phonograph pick-up in reverse, where the audio is converted to mechanical motion. The cutting stylus, mounted in the head, cuts a precise spiral groove across the plate spinning at an exact speed of 33 & 1/3 or 45rpm and vibrates to transfer the recording.

Image Source: Abbey Road Studios

Once the cut has taken place, lacquers are processed, firstly to a negative using nickel and an electroplating process, then again to create a positive. These are then plated once more to form the stampers (negatives again), which are then used to press the final records. DMM Coppers are processed in a similar way, though they require less electroplating steps as they can be processed directly to stamper.

If you'd like more info on lacquers, the differences among lacquer mastering and DMM or any other enquiry, please get in touch with us through email or social media, we'll be more than happy to clarify anything.

If you would like to read the official statement released by Apollo, click here